1. The history of Bellmer's establishment and development:

Bellmer is an international high-tech mechanical engineering company specializing in the design, manufacturing, and installation of premium machines with two main focuses: Paper Technology, concentrating on paper and board packaging machines, and Separation Technology, focusing on water and sludge treatment. Established in Germany in 1842, the company is family-owned and currently employs over 750 staff across 16 locations worldwide.

Expertise and motivation are the keys to success: our experts are always ready to support you on-site with services, requests, and equipment. We optimize your operations globally with our international team. We are prepared to become your personal and flexible partner, contributing to your company's success through innovative solutions. All our products are manufactured in Germany and Finland.

2. Scope of Supplying

2.1 Paper Technology

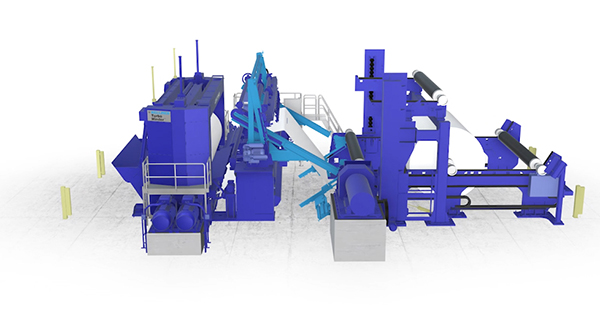

Together with you, Bellmer advises, plans and designs plants or modernization projects for the pulp and paper industry. Paper Technology stands for innovative and efficient solutions for your paper production. From the approach flow via the wire section, press part and drying section up to the pope reel, complete paper machines can be supplied ready to use.

Based on our experience, we develop machine building solutions with integrated control technology. They are implemented in a turnkey way and commissioned & started up by Bellmer specialists.

No matter, if it is fine paper or packaging paper or anything else, for Bellmer your needs are the top priority!

In addition to a joint optimization phase, we offer our 24h service through 365 days a year as a standard feature for our customers.

2.1.1. Approach flow System

Turbo Approach Flow Systems: The Bellmer approach flow systems ensure efficient fiber treatment with Screens, Refiners, Deflakers and Cleaners from our TurboLine.

Advantages:

Get more information at https://www.bellmer.com/paper-technology/approach-flow-systems/

2.1.2 Turbo Wet-end Solution

No matter what kind of fiber web you aim to produce, what speed you choose to run, and whether you use primary or recycled fiber – the wet end holds the key to any best sheet. Our TurboSeries: HEADBOX, PRESS ROLL SHAKER, WIRE SECTION, DANDY ROLL, PRESS SECTION, SHOE PRESS from Germany and Finland provides individually designed products for the wet end area starting from the headbox via the wire section to the press section. Our technical design service incorporates stock characteristics, space-technical considerations as well as specific automation solutions.

Treat your wet end to the attention it deserves by working with Bellmer. You will find us highly focused on your results, and flexible in our approach. Decades of satisfied customers are the result.

Get more information at: https://www.bellmer.com/paper-technology/wet-end/

2.1.3. Turbo Dry-end Solution

Our TurboSeries features products specifically engineered for the dry end area, from single and multi-tier DRYER SECTIONS, via FILM PRESSES, COATERS, CALENDERS to REELING technology.

Our designs account for all paper characteristics, energy-related technical considerations as well as specific automation solutions. Treat your dryer section to the attention it deserves by working with Bellmer. You will find that we are totally focused on your results, and flexible in our approach. Bellmer’s engineers and designers have always sought new ways to improve what we do. Decades of satisfied customers are the result.

Get more information at https://www.bellmer.com/paper-technology/dry-end/

2.4.1. Coating & Sizing – TurboLine:

The coating and sizing units of our TurboLine improve your paper surface perfectly. Our specialists design, customize and manufacture in Germany COATERS, SIZERS, FILMSIZERS and CURTAIN COATER at highest perfection standards. No matter if you are searching for more paper strength, smoother paper surface or just fantastic printability here you find the right solution. Choose from our Pondsizer, Filmpress, Blade coater or Curtain coater. To make your project complete, we also supply the right pulper for highest efficiency along.

FilmSizers:

Get more information at https://www.bellmer.com/paper-technology/coating/

2.1.5. Reeling and Winding - Winder

The use of innovative reeling technology is the pre-requisite of a successful production of your papers. Only perfectly reeled papers can be further processed in the quality produced by you. With the TurboReeler Family, we have created our reeling solutions in a modular way, ready to cope with the most versatile demands. This will help you to install the best solution for your paper web thus ensuring a long and problem-free operation with your production line for many years.

TurboWinder

GapCon´s TurboWinder is based on the two-drum principle and is tailor-made to meet the capacity and technological requirements of each customer while complying with all current applicable safety regulations.

Module of Winder:

Get more information at https://www.bellmer.com/paper-technology/winding-reeling

2.1.6. Automation - BellSystems

The Bellmer BellSystems ensure safe, intuitive operation of Bellmer Products around the world. Automation engineers in Spain, Finland, and Germany create the concepts, programs, and implementation of automation to the smart products for any paper or board production line. Internet of things, IOT or industry 4.0 started in reality already in the 80s, when we founded our automation department. Repetitive tasks or continuous optimization loops can be managed by smart products in algorithms safely and efficiently.

Three Base concepts BellCheck, BellLife, and BellSelf are designed to facilitate the operator´s daily life. Subject to the case of application, our experts adapt the BellSystems ideally to our scope of services and supply. Expect intuitive controls to ensure permanent supervision of all movements and positions. Anticipate excellent start up and great runability.

Get more information at https://www.bellmer.com/paper-technology/automation/

2.1.7. Service for Paper Technology

You can reach our service division offering the most diverse performances round the clock for 365 days so that your perfect production process can be ensured to the greatest possible extent. We give you advice and assistance, we supply spare parts and we are prepared to carry through in our in-house workshops repairs and assembling jobs at top quality in a reliable and fast way:

Get more information at https://www.bellmer.com/paper-technology/service/

2.2. Separation Technology - Paper Industry

Our company roots come from 1842 as of the paper industry. Consequently, we are specialists in this field. Typical challenges of a paper manufacturing process are our daily business. We exactly know our customers’ requirements and difficulties. A production shutdown is costly and needs to be avoided. Therefore we only deliver best quality machines, to assure a smooth, continuous operation process. In short, Bellmer is one of the main market leader in this industry. Today there exist more than 500 paper production plants with Bellmer equipment. This clearly underlines the high expertise of Bellmer in the paper industry field. We set qualilty standards with our constant improvements and innovations.

Get more information at https://www.bellmer.com/separation-technology/paper-industry/ - https://www.bellmer.com/screw-press/

3. Our Customer

We’re long term support for our consumer: Vinakraft, Lee&Man, Chengloong, Donghai, Saigon Paper, Vinapaco…No matter the purchase is direct or through Vision JSC, we always support/co-operate with you to optimize your machine with cost effeciency.

4. News & Contact

Get more information at https://www.bellmer.com/news/

or contact us through email: sale2@visionjsc.com.vn for your needs.

Hotline: 0902951129 or 0914363745